Get in touch

+63 2 8862-3094

0917-899-5645 (Globe)

0947-994-8123 (Smart)

0917-899-5645 (Globe)

0947-994-8123 (Smart)

sales@dpti.com.ph

-Biodiesel- DSOL Purification System

Jul 30, 2021

We are pleased to inform you that we can now supply our

D-SOL Purification System. The system consists of

D-Sol Adsorbent and our DPTI Filtration System and Mixing tank to efficiently improve feedstock quality to enhance efficiency and productivity of Biodiesel plants. Our D-SOL is the original

Dry Wash Agent in the Biodiesel Market. The use of

D-SOL

in the Post Transesterification process is much more efficient than the conventional water wash or Ion exchange Resin Technology.

Disadvantage using Water Wash requires pretreatment and decreased yield due to loss in effluent, time & cost of drying methyl esters, high soap causing emulsification, effluent treatment and disposal cost, long gravity separation time and costly centrifuges, Sterol Glucosides not removed.

While in Ion exchange Resin, it does not provide Depth filtration benefits (175 microns). Cannot be regenerated for soap/ catalysts, resin is not removing the soap/catalyst (ion exchange only). Aside from that it is sensitive to upsets in the system, high soap, water etc., Extra column may be required when excess glycerin is present and resin disposal.

D-SOL Adsorbent Purification

removes BOTH particles and soluble impurities and provides depth filtration down to 1 micron or less giving you higher quality biodiesel and removal of Sterol glycosides. The benefits are:

- No water effluent stream

- No emulsification

- Improved Oxidative Stability (OSI)

- Minimal yield loss

- Expedite Purification process

- Allows for removal of Sterol Glucosides

- Can be used to reprocess of off- specs materials

- Achieves regulatory specifications

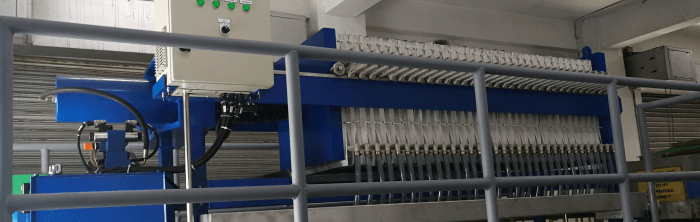

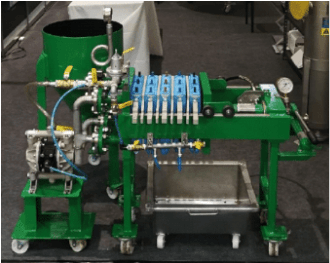

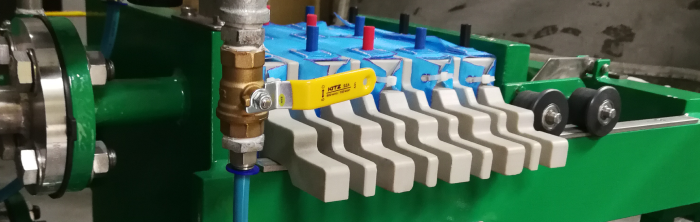

Initially we can assist you in your test via your laboratory ,then we can also do a performance trial / Pilot test at site with our portable filtration system (refer to below photo) and assist you during commissioning of the D-SOL Purification System plant.

Attached is our Biodiesel Filtration product Information for your reference and Biodiesel frequently asked questions.

We would be happy to discuss to you further the system, please inform us your Annual Plant capacities in Million Liters to come up with Price / Liter of purified Biodiesel as well as indicative cost of filtration systems.

Very truly yours,

Previous Posts

31 Jul, 2021

The goal of filter press pilot testing is to collect the data required to accurately size a full-scale filter press system.

Typical data collected includes cake solids, cake density, total processing time, if desired filtrate suspended solids, slurry feed solids, slurry pH, actual chemical conditioning dosages, and maximum operating pressure. Depending on the process requirements the total processing time may be further subdivided into steps such as filtration, cake wash, final squeeze, and cake air blow.